Tesla shares plummet US$ 50 billion

CEO Elon Musk outlined Tesla’s plans to cut electric vehicle battery manufacturing and design costs so radically that a $ 25,000 car that drives itself will be possible on the company’s “Battery Day” Tuesday fair, US time. But the automaker’s shares plummeted when Musk predicted the move could take three years or more.

Altogether, Tesla’s market capitalization has plunged $ 50 billion since Monday’s close, with investors eliminating $ 20 billion of it in just two hours after the closing of deals on Tuesday.

Musk acknowledged that Tesla does not have its ambitious vehicle and battery designs and manufacturing processes fully completed. Tesla has often failed to meet production targets.

Tesla expects to be able to build up to 20 million electric vehicles a year. This year, the entire auto industry expects to deliver 80 million cars worldwide.

Tesla shares, which closed on Tuesday with a 5.6 percent drop, fell another 7 percent in after-hours trading.

Building an affordable electric car “has always been our dream since the company started,” Musk told an online audience of more than 270,000.

However, Musk described a new generation of batteries for electric vehicles that will be more powerful, last longer and have half the price of the company’s current cells.

Tesla’s new larger cylindrical cells, called 4680, will provide five times more energy, six times more power and 16% greater steering range, Musk said, adding that total production is about three years away.

“We don’t have an affordable car. This is something we will have in the future. But we have to reduce the cost of the batteries,” said Musk.

To help cut costs, Musk said Tesla planned to recycle battery cells in its Nevada “gigafactory” while reducing cobalt – one of the most expensive battery materials – to practically zero. It also plans to make its own battery cells in several highly automated plants around the world.

Tesla will initially produce the new battery cells on a new assembly line near its vehicle plant in Fremont, California, with planned production reaching 10 gigawatt hours per year by the end of next year. Tesla and its partner Panasonic now have a production capacity of around 35 gWh in the Nevada battery “gigafactory”.

Tesla plans to rapidly increase battery production in the next few years, to 3 terawatt hours per year, or 3,000 gigawatt hours – about 85 times the capacity of the Nevada plant.

The automaker plans to produce the new cells through a highly automated continuous motion assembly process, according to Drew Baglino, Tesla’s senior vice president of powertrain and energy engineering.

Musk acknowledged that Tesla does not have its new battery design and manufacturing process completely complete.

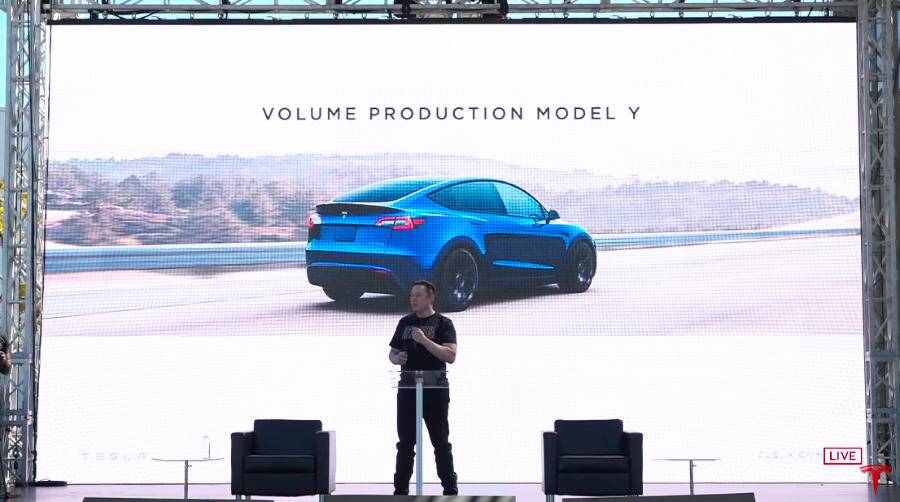

At the opening of the event, which drew more than 270,000 online viewers, Musk took the stage in a black T-shirt and jeans while about 240 shareholders – each seated in a Tesla Model 3 in the company’s parking lot – honked in approval.

Before the event, Tesla’s stock closed at $ 424.23 on Tuesday, down 5.6% after Musk tweeted on Monday night that the battery improvements to be revealed at the event would not reach “production high volume “until 2022. up and down in the after-hours trade.